Tain Wastewater Treatment Works (WwTW) Upgrade

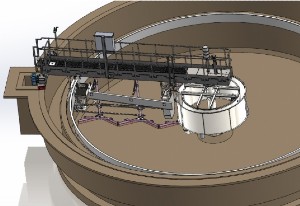

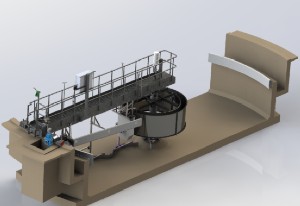

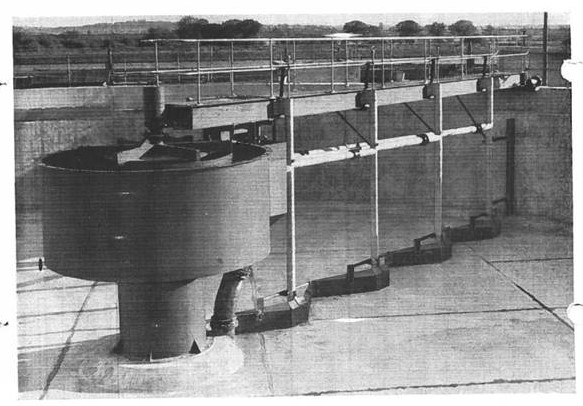

Recently we worked on the supply and installation of a new Hydrostatic Siphon De sludge Bridge Scraper for a new Final Settlement Tank at Tain WwTW, in collaboration with ESD and Black and Veatch, for Scottish Water. The design of the new bridge scraper was to replicate and replace an existing one on site.

This innovative Bridge Scraper has a mechanism that is designed to remove light sludges in the shortest possible time and is particularly suited to the activated sludge process, the efficiency of which depends upon the rapid return of sludge in a fresh condition. The equipment is equally suitable for Humus tanks from which the sludge should be withdrawn before denitrification can take place.

The design allows for a flat floor tank which is simple and economical to construct and reduces the volume of concrete required.

How does it work?

The rotating half bridge scraper operates in a flat-bottomed Final Settlement Tank with a siphon desludging system. The sludge collects on the bottom of the tank, as the bridge rotates scraper blades collect the sludge at draft tubes. The sludge is transferred through these draft tubes and collected in a sludge reservoir. It then flows through the siphon pipe into the sludge launder and out of the launder and tank by a decant pipe. The layer of scum at the top of the effluent is removed via a beach and blade scum removal system.

The half bridge scraper is fitted with a park position, when called to park the bridge stops at this location, allowing the operator to access the bridge.

The bridge is fitted with a heating element which prevents ice build-up on the tank wall in front of the drive wheel. The heating element will be turned on once the temperature drops to a pre-set level on the temperature switch.