Bridge Scrapers supplied for £3.8M upgrade and maintenance project

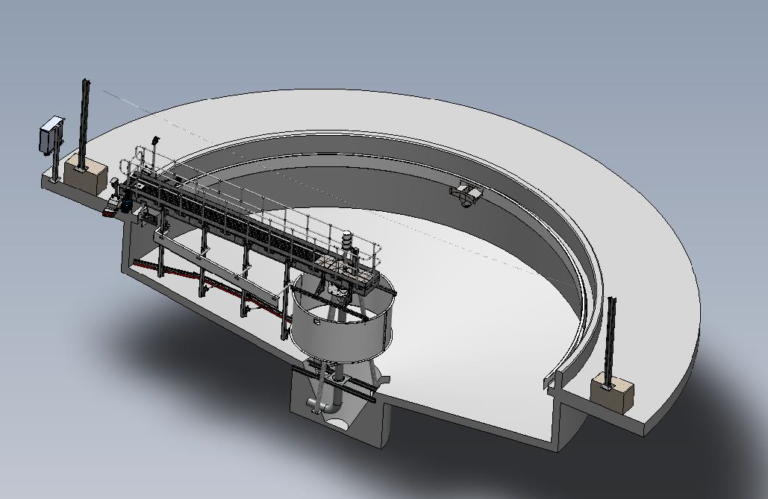

4No. rotating half bridge scrapers supplied for two 16.5M primary settlement tanks (PSTs) at Haddington Wastewater Treatment Works by Colloide Engineering Systems. Colloide contracted for the detailed Mechanical & Electrical design, supply and delivery of the bridge scrapers. ESD acted as the main contractors and carried out the civil engineering works.

Haddington Sewage Works is situated to the north of Amisfield Walled Garden. Colloide’s bridge scraper installations are part of a £3.8 million upgrade and maintenance project by Scottish Water and their alliance partners ESD. The work, which includes upgrades to the treatment process, will ensure that the works can continue to operate effectively now and in the future.

Scope of work

Download our Case Study on Haddington Waterwaste Treatment Works (WwTW) to find out more.

Why choose Colloide?

We work extensively providing water and wastewater treatment solutions across municipal and industrial sectors, from water treatment plants and technologies for some of the UK’s largest water companies to effluent and water handling solutions for industrial clients. We design, manufacture and install circular and rectangular bridge scraping systems (plastic and steel) for settlement and flotation tanks. Our equipment is available on a short lead time and designs are suitable for heavy duty applications, delivering long life with minimum maintenance.

Click here to find out more about our bridge scraper features and benefits.